LNG/Cryogenic Loading Arms

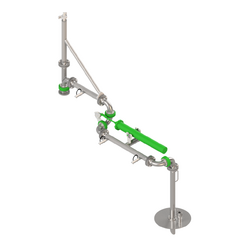

A cryogenic loading arm is a specialized piece of equipment used to transfer liquefied gases at extremely low temperatures, such as Liquefied Natural Gas (LNG), Liquid Nitrogen, or Liquid Oxygen, between storage tanks and transportation vehicles like ships, railcars, or tank trucks. These loading arms are designed to handle cryogenic fluids that are stored at temperatures as low as -196°C (-320°F), requiring specialized materials, engineering, and safety considerations.

Cryogenic loading arms are critical in industries where maintaining the fluid in its low-temperature, liquefied state during transfer is essential to prevent vaporization, product loss, or hazardous conditions. The arms must also ensure flexibility, ease of operation, and safety for operators while complying with strict regulatory standards.

Key Components of a Cryogenic Loading Arms

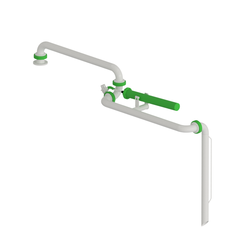

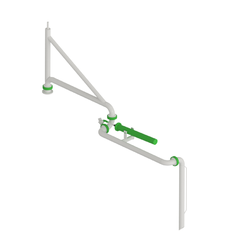

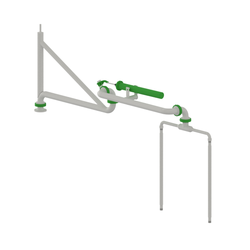

Loading Arm Structure:

- The loading arm consists of articulated joints connected by pipes designed to transfer cryogenic fluids. These joints allow flexibility and movement during the loading or unloading process.

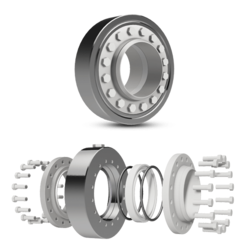

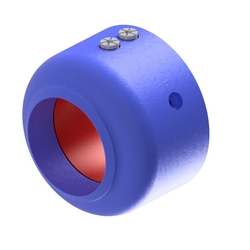

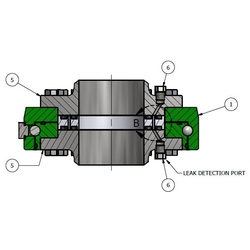

Swivel Joints:

- Swivel joints are critical for providing flexibility and range of motion to the loading arm. These joints must be designed to withstand extreme low temperatures without failure while maintaining a leak-proof connection.

- Cryogenic swivels are constructed from stainless steel or other materials capable of handling low temperatures and are engineered to maintain smooth movement with minimal friction.

Emergency Release System (ERS):

- Cryogenic loading arms are typically equipped with an Emergency Release System (ERS) to quickly disconnect the arm in case of an emergency, such as a ship drifting or unexpected vehicle movement. The ERS is designed to release the loading arm without damaging it or spilling cryogenic fluids.

- The ERS includes safety valves that automatically shut off the flow of cryogenic liquid upon disconnection to prevent spills, fires, or other hazardous conditions.

Breakaway Couplings:

- These couplings allow for the safe disconnection of the loading arm in the event of accidental pull-away or excessive tension on the arm. Upon disconnection, they automatically seal both ends of the pipe, preventing any leakage of cryogenic fluid.

must also be insulated and engineered to handle the low temperatures of the liquefied gases.

Positioning and Balancing System:

- Cryogenic loading arms require a balancing system, often consisting of counterweights, hydraulic cylinders, or spring balance mechanisms, to facilitate smooth operation and positioning. The balancing system allows operators to move and position the arm with minimal effort, even in cold environments where manual handling becomes difficult.

Materials and Design Considerations

Material Selection:

- Cryogenic loading arms are constructed from stainless steel or nickel alloys that can maintain mechanical integrity at low temperatures without becoming brittle. These materials offer excellent thermal resistance and are less prone to corrosion and embrittlement compared to standard carbon steel.

- Seals, gaskets, and O-rings used in cryogenic applications must also be made from materials that can withstand both cryogenic temperatures and the specific chemical properties of the fluids being handled. Common materials include Teflon and Elastomers designed for cryogenic service.

Temperature Monitoring:

- Temperature sensors are often integrated into the system to monitor the cryogenic fluid's temperature during the loading or unloading process. This data can be fed into control systems to ensure that the fluid remains within the acceptable temperature range throughout the transfer.

Safety Features

Emergency Shutoff Valves (ESV):

- These valves are installed in strategic locations within the loading arm and are designed to immediately shut off the flow of cryogenic fluids in the event of an emergency. They are typically integrated into the control system and can be triggered manually or automatically based on system conditions.

Fire and Gas Detection:

- Given the potential hazards of liquefied gases, especially flammable cryogenic fluids like LNG, loading facilities are often equipped with fire and gas detection systems. These systems detect leaks or fire hazards and can automatically initiate shutoff procedures.

Personnel Protection:

- Operators working with cryogenic loading arms must wear appropriate personal protective equipment (PPE) such as cryogenic gloves, face shields, and thermal protective clothing. Safety training is essential to ensure operators understand the risks associated with cryogenic fluids and the proper handling techniques.

Applications

LNG Terminals:

- Cryogenic loading arms are widely used in LNG export and import terminals to load and unload LNG between storage tanks and ships. Their ability to handle large volumes of liquefied gas safely makes them ideal for the LNG industry.

Industrial Gas Facilities:

- Facilities that produce or utilize liquefied industrial gases like nitrogen, oxygen, or argon also use cryogenic loading arms for transferring these gases into storage tanks, trailers, or railcars.

Space Industry:

- The space industry relies on cryogenic loading arms for fueling rockets with liquefied gases like Liquid Oxygen (LOX) and Liquid Hydrogen (LH2), which are used as propellants in many space launch vehicles.

Understanding the Value of Cryogenic Loading Arms

Cryogenic loading arms are essential equipment for the safe and efficient handling of liquefied gases at extremely low temperatures. Their design incorporates specialized materials, advanced insulation techniques, and a range of safety features to ensure that the fluids remain in their liquid state during transfer while protecting both personnel and equipment from the hazards associated with cryogenic fluids.

By adhering to stringent engineering standards and employing robust control and emergency systems, cryogenic loading arms play a critical role in the operations of industries such as LNG, industrial gas production, and the space sector.

Our philosophy of quality, safety, and service combined with our capacity to ship products quickly--often within half the time of our competitors--is what sets us apart. When necessary, we also offer in-field replacement and adjustment services as well as factory refurbishment and rebuild services. Contact us today to learn more about our top loading arms.