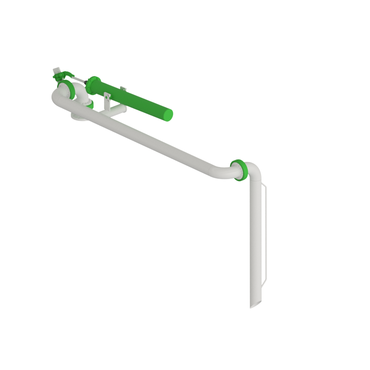

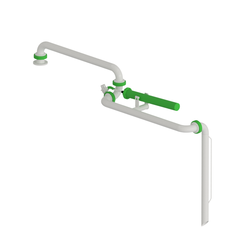

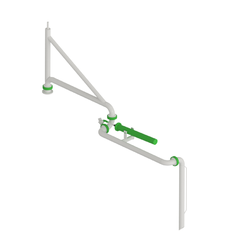

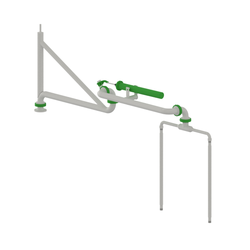

Fixed Reach & Single Compartment Top Loading Arm

Overview

The TL-54 is a configurable top-loading arm engineered for safe, repeatable truck and rail loading. Its counterbalanced design and low-torque swivels give operators smooth, precise control, while the arm geometry is tailored to your rack to minimize alignment time and operator effort. Options for vapor management, thermal protection, and safety accessories let you match the TL-54 to your media and environment.

Why customers choose the TL-54

- Smooth, balanced handling—easy positioning with minimal operator effort.

- Reliable swivel design with long-life sealing to reduce maintenance.

- Custom-fit reach/drop envelope for tight or multi-lane rack layouts.

- Durable construction and coatings for terminal and chemical service.

- Safety upgrades—parking/locking hardware, drip management, grounding.

- Service-friendly with accessible wear parts and common seal kits.

Typical uses

- Refined products and solvents with vapor recovery as required.

- Stainless builds for corrosive or high-purity chemical service.

- Asphalt or viscous media with integrated heat-trace and insulation.

- Truck islands and rail spots requiring repeatable, precise alignment.

How it works (simple)

- Operator swings the balanced arm into position.

- Final alignment with drop hose or pipe; secure connection.

- Open valves; monitor flow and vapor return as applicable.

- Close, drain, disconnect; return arm to parking stand/lock.

Configuration options

- Sizes & materials: 2", 3", 4", 6" in carbon steel (painted) or 304/316 stainless.

- Seals: FKM (Viton®), NBR, PTFE-based, others to match compatibility and temperature.

- Counterbalance: Adjustable spring-assist, pneumatic and hydraulic available.

- End-of-arm: flanged or threaded outlet; tapered drop tube/nozzle (fixed or adjustable); vapor cone/hood or dedicated vapor return arm; deflector/splash cone; drip management; drain/foot valve and isolation valves as specified.

- Thermal: Insulation jackets and heat-trace kits for cold climates and heavy products.

- Safety/handling: Mechanical locking bar, travel stops, grounding/bonding clamp, drip tray.

- Instrumentation: Sample ports, gauges, purge, and valve packages on request.

Customizable envelope

We configure the arm’s working reach, drop length, and rotation stops to match rack height, vehicle variation, and clearances—improving ergonomics and cutting cycle time.

Maintenance & support

Each arm includes IOM instructions. Routine checks typically include swivel inspection and lubrication (if applicable), seal condition, counterbalance settings, and visual hardware inspection. Seal kits and common wear items are stocked for quick maintenance.

FAQs

- Is the TL-54 compatible with vapor recovery? Yes—use a vapor cone/hood or a dedicated vapor return arm.

- What sizes are available? Standard 2"–6"; 3" and 4" are most common.

- Can you provide heat-trace and insulation? Yes—factory-integrated packages available.

- What maintenance does it require? Periodic swivel and seal checks plus counterbalance verification per the IOM schedule.

- Is it for truck and rail? Yes—geometry is tailored to either layout.