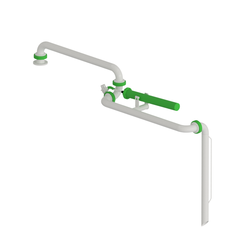

Variable Reach Top Loading Arm (TL-544)

Overview

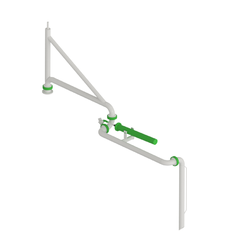

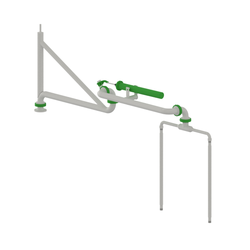

The TL-544 is a heavy-duty, configurable top-loading arm designed for safe, repeatable product transfer at truck and rail racks. It combines smooth counterbalanced movement, low-torque swivels, and a customizable reach/drop envelope so operators can position the arm accurately with minimal effort. Add vapor control, thermal options, and safety accessories to match everything from refined fuels to asphalt and specialty chemicals.

Why customers choose the TL-544

- Balanced, one-hand operation that reduces operator fatigue and speeds turnarounds.

- Low-leak, low-torque swivel design for long seal life and lower maintenance.

- Built-to-fit geometry (reach, drop tube, rotation stops) for existing rack constraints.

- Rugged construction and coatings for terminal environments and harsh service.

- Safety accessories—parking stands, position locks, drip management, grounding/bonding.

- Field-serviceable components with accessible grease points and common seal kits.

Typical uses

- Refined fuels top-loading with tapered drop tubes and vapor recovery.

- Chemical service in stainless builds with compatible elastomers.

- Asphalt/heavy products with insulation and heat-trace for cold-weather performance.

- Multi-lane truck islands and single-spot rail where precise envelope control matters.

Configuration options

- Piping size & materials: 2", 3", 4", 6" in carbon steel (painted) or 304/316 stainless.

- Seals: FKM(Viton), NBR, PTFE-based and others to suit media/temperature.

- Counterbalance: Adjustable spring-assist Pneumatic and Hydraulic available.

- End-of-arm: flanged or threaded outlet; tapered drop tube/nozzle (fixed or adjustable); vapor cone/hood or dedicated vapor return arm; deflector/splash cone; drip management; drain/foot valve and isolation valves as specified.

- Thermal: Insulation jackets and integrated heat-trace kits for viscous products.

- Safety & handling: Mechanical locking bar, travel stops, grounding clamp/monitor, drip tray.

- Instrumentation: Sample ports, gauges, and valve packages on request.

Customizable envelope

We tailor the working reach, drop length, and rotation limits to your rack height, island spacing, and vehicle variation. The result is a loading motion that feels natural to the operator and consistently hits the same spot—cutting alignment time and reducing strain.

Maintenance & support

Arms ship with clear IOM guidance. Preventive checks include swivel inspection, counterbalance verification, and seal/grease intervals based on service. Seal kits and common wear parts are stocked; our team can assist with start-up, training, or retrofit of accessories.

FAQs

- Truck and rail compatible? Yes—geometry is set for your rack heights and clearances.

- Vapor recovery ready? Add a vapor cone/hood or a dedicated vapor return arm.

- Heat-trace/insulation available? Yes—common on asphalt/heavy-oil builds.

- Lead time? Standard configurations are quick; engineered options vary—ask for current lead time.

- Service temperature/pressure? Built to your spec; we’ll match materials and seals to media and conditions.